Introduction

Which technologies will we use to generate electricity in the future? This is a central question not only in politics, but also in research and in society. As competitiveness also plays an important role here, it ultimately comes down to the levelized cost of energy (LCOE) is what counts.

LCOE = sum of all costs of a power plant / total electricity over the entire service life

For this reason, companies are concentrating on achieving a lower LCOE compared to conventional electricity generation. The biggest advantage of renewables is that there are no costs for fuel (e.g. sunlight, wind, water).

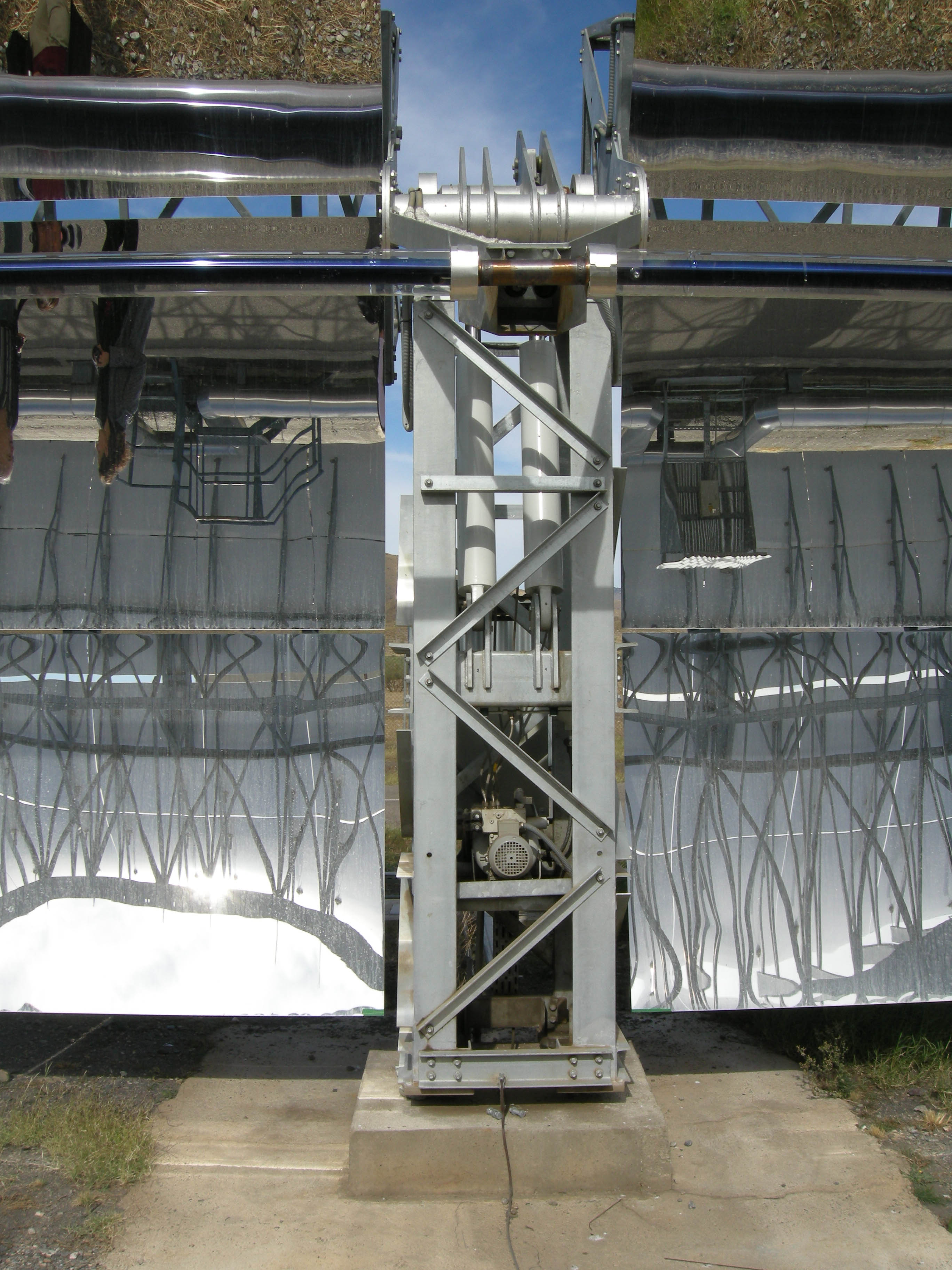

Solar panel of a CSP solar power plant

Solar energy

On the basis of solar energy is a good example of the effect of sensor technology on yield. First of all, we need to distinguish between two types of electricity generation:

The photoelectric effect converts sunlight directly into electricity (photovoltaics).

The sun's radiation generates heat, which ultimately generates electricity via water vapor (solar thermal)

Tracking systems (solar trackers) align both photovoltaic modules and reflectors or mirrors with the sun. On the one hand, this leads to higher efficiency. On the other hand, they result in higher costs for the system. Engineers and planners therefore carefully calculate whether a tracking system (single-axis or dual-axis) will help to reduce overall costs. As the annual costs for maintenance and operation are also part of the calculation, a fixed installation may be considered as a result.

Single-axis trackers for solar energy

Tracking system

The BTL in the installed application indicates current deflection of the rooftop construction. In the case that optimal indicators have been exceeded after a heavy snowfall, the technical crew directs a shoveling team in order to prevent construction damage and the resulting catastrophe.

Single-axis tracking systems align photovoltaic modules on the one hand and parabolic troughs or linear Fresnel collectors on the other with the sun. Firstly from east to west and secondly over the course of the day according to the position of the sun. Depending on the required tracking accuracy, various sensors perform this task.

-

Most photovoltaic trackers use electric linear drives in which very often inductive sensors feedback the position. As a result, they are cost-optimized and are standard in the actuators.

-

There is also the possibility of using inclination sensors to use inclination sensors. They are mounted directly on the rotating shaft and provide angular feedback (e.g. in linear Fresnel systems). Inclination sensors are mounted on the moving part of the structure. This encourages the constantly moving cables to wear out over time. Ultimately, this cable wear can lead to failures.

-

For high-end tracking in parabolic trough systems, we supply magnetic tape systems provide position feedback. The magnetic tape is mounted around the shaft and the sensor head is attached to the frame of the tracker. The sensor counts the pulses with micrometer precision. This enables continuous and wear-free positioning.

Biaxial trackers for solar energy

Dual-axis systems for tracking basically position all technologies used:

-

Concentrated photovoltaic modules (CPV)

-

Parabolic reflectors (dish)

-

Mirrors (heliostats)

But especially solar thermal power plants so-called Concentrated Solar Power plants (CSP) require precise accuracy. Heliostats must therefore direct a lot of light onto a central receiver on a tower in the middle of the heliostat field. This then leads to the high temperatures achieved for the water-vapor cycle. As there is an azimuth axis and an elevation axis two positioning systems must also measure these angles.

Firstly inclination sensors can measure the elevation angle depending on the position of the sun. They are based on the MEMS principle or are fluid-based. Secondly, the azimuth angle must be measured. But the principles are not suitable for measuring angles from east to west (azimuth). An alternative is therefore to detect the position with integrated rotary encoders directly on the drive. At this point there is play, which affects both the indirect measurement and the accuracy. However, this is of the utmost importance, as the heliostats can be many hundreds of meters away from the central receiver. Magnetically coded position and angle measurement systems can be mounted on both shafts (azimuth and elevation). This results in direct measurement of the angles with maximum accuracy.

In addition to solar energy, hydropower will also play a central role in the electricity mix of the future. It is the oldest source of energy and is already an integral part of the electricity mix in many countries around the world. However, there is also great potential in the use of ocean energy, such as tides and waves. Further information on applications in both renewable energies and conventional power plants can be found in our brochure on the energy sector. It describes the areas of application of the Balluff portfolio in the industry.

At Balluff, we specialize in providing cutting-edge sensor solutions for the steel industry. With years of experience and a deep understanding of the unique challenges faced by steel manufacturers, we offer a wide range of sensors and automation solutions tailored to meet the demands of this dynamic industry.

Our team of experts is dedicated to helping steel plants optimize their processes, improve product quality, and enhance operational efficiency. Balluff has the expertise and solutions to drive success in the steel industry.

Contact us today to learn more about how Balluff sensors can transform your steel manufacturing operations and take your business to new heights of success.